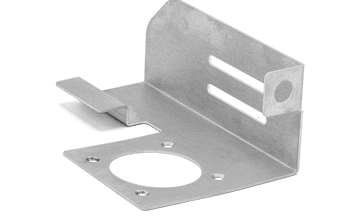

Sheet Metal Fabrication

Our Capabilities for Sheet Metal Fabrication

Laser Cutting

We use laser cutting to make accurate, waste-free cuts. Our laser cutters can cut materials up to 6mm thick with an accuracy tolerance of ±0.00787 inches (0.2mm). Sharp, clear lines are assured when we carve convoluted forms and patterns in multiple materials. Precision sectors, including aerospace and automotive, need this expertise since every millimeter matters.

Bending

Our bending uses contemporary press brakes with accurate dies. We can obtain repeatable bending angles of up to ±1.0° for manufacturing structural components like brackets and frames. Metal sheets from 1 to 6mm thick allow for production flexibility without losing precision. Our bending procedures are developed for pace and reproducibility, so every product meets high requirements.

Punching

We punche sheet metal for precise holes and cutouts. Our punching machines are calibrated for different thicknesses and materials for clean, burr-free output. The procedure helps manufacture panels, enclosures, and other parts with tight-tolerance perforations.

Welding

Our experts use MIG and TIG welding to make solid, lasting welds across multiple metals and thicknesses. We use high welding standards for structural and ornamental integrity. The construction and electronics sectors employ chassis and large enclosures, which require welding.

Main Materials for Sheet Metal Fabrication

|

|

Tolerance for Sheet Metal Fabrication

- Cutting Feature: ±0.00787 inches (0.2mm)

- Bending Angle: ±1.0°

- Bending Edge: ±0.010 inches (0.254mm)

- Hole Diameter: ±0.005 inches (0.127mm)

- Overall Dimensions: ±0.015 inches (0.381mm)

Application for Sheet Metal Fabrication

ShanenTech manufactures several functioning components and assemblies using sheet metal fabrication. We make antenna mounts and chassis for telecommunications, medical enclosures for healthcare, and device casings for consumer electronics. We serve car manufacturers with brackets and engine mounts for their requirements. Our fast manufacturing cycles (3–15 days) empower us to stick to short deadlines and launch our customers’ products on time. Precision and credibility render us an invaluable asset in any business that needs top-notch sheet metal products.

- Electrical enclosure

- Parts for computer electronics

- Chassis

- Brackets

- Cabinets

- Mounts

- Appliances

Contact Us to Start Your Sheet Metal Project

Our sheet metal fabrication services from prototype to production ensure high quality, fast delivery and competitive prices.