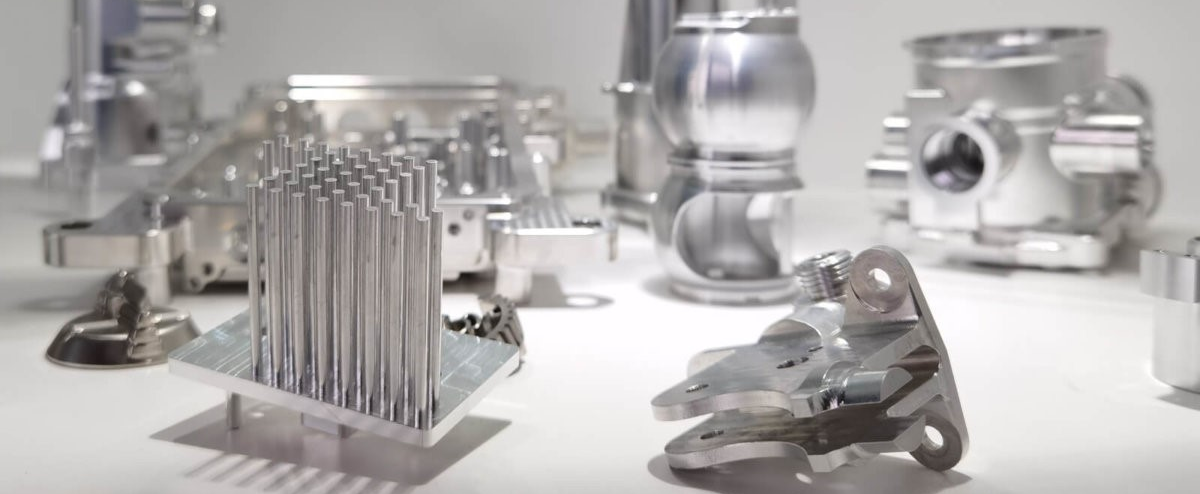

CNC Machining Aluminum

Our Aluminum CNC Machining Capabilities

State-of-the-art CNC Machines and Technology Used by ShanenTech

- Multi-axis CNC machining centers.

- High-precision turning centers with live tooling capabilities.

- Advanced milling machines with 5-axis interpolation.

- Integrated CAD/CAM systems for multifarious geometries.

- Automated robotic arms for consistent material handling.

- High-speed machining (HSM) technologies for better efficiency.

- Real-time monitoring systems for machining process optimization.

- Laser engraving and marking machines for detailed customization.

Range of Aluminum Grades Processed and Their Applications

- Aluminum 2024: aerospace components due to high strength and fatigue resistance.

- Aluminum 6061: construction and auto parts for weldability and corrosion resistance.

- Aluminum 7075: aerospace and military applications for superior stress resistance.

- Aluminum 5052: marine environments for saltwater resistance and formability.

- Aluminum 6063: architectural uses for smooth surface finish and structural strength.

- Aluminum 1100: electrical applications for thermal conductivity and corrosion resistance.

Customization Options Available for Clients

As CNC machining leaders, we provide considerable customization for customer demands. Precision-engineered solutions are our specialty, whether manufacturing prototypes or mass-produced products. We can customize your projects’ surface treatments, machining tolerances, and features. We provide post-processing services, including anodizing, heat treatment, and laser engraving, so your components satisfy the highest quality and performance specifications.

Benefits of Aluminum for CNC Machining

Physical Properties of Aluminum for CNC Machining

- High strength-to-weight ratio

- Excellent thermal conductivity

- Good electrical conductivity

- Natural corrosion resistance

- Non-magnetic properties

- High reflectivity

- Ductility

- Recyclability

Cost-Effectiveness of Aluminum Compared to Other Metals

Due to its richness and lower raw material cost, aluminum is cheaper than stainless steel and titanium. Aluminum machining uses less energy, which cuts production costs for us and our clients. The efficiency, plus aluminum’s long life and recyclability, may justify the original outlay.

Ease of Machining and Environmental Benefits of Using Aluminum

The machinability of aluminum allows us to achieve high precision with fewer tool changes, which speeds up production. Aluminum sheets and scrap can be recycled, reducing waste and pollution. These benefits help ShanenTech achieve its sustainability goals while reducing material costs and increasing productivity. It complements our ecological control and global green manufacturing trend.

Applications of CNC Machined Aluminum Products

- Aerospace: We perform precision-engineering aluminum brackets, fittings and flanges to reduce weight and meet high altitude and high-speed strength requirements.

- Automotive: Skeletal components and custom aluminum fittings expand the use of our CNC-machined products in automotive systems.

- Electronics: We make aluminum enclosures, heat sinks, and chassis for efficient electronics that facilitate thermal management and electromagnetic shielding.

- Construction: We use lightweight aluminum to create fittings, structural components, and ornamental elements that are sturdy, elastic, and simple to install.

Quality Assurance and Certifications

For production accuracy, ShanenTech uses SPC and real-time monitoring for quality control. Our facilities are certified for ISO 9001:2015 quality management systems standards. It proves that we can meet customer and regulatory requirements in production.

Why Choose ShanenTech for Aluminum CNC Machining

- With over 13 years of experience

- One-to-one service from design to production to make your project finished smoothly

- Promote the sustainability of certain projects with competitive prices and fast turnaround times

- Aluminum CNC machining with tight tolerance

- Customized solutions for project needs, which are highly valued by our customers

Contact Us Now to Start Your CNC Machining Aluminum Project

Our CNC machining services from prototype to production ensure high quality, fast delivery and competitive prices.