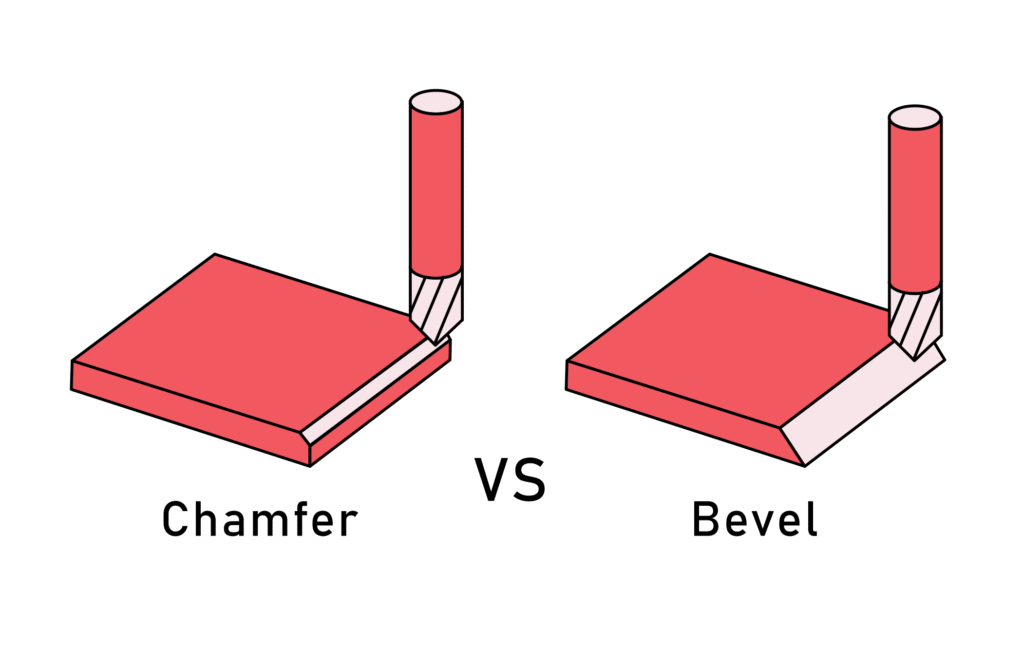

There are some similarities between bevel and chamfer, but there are also clear differences, and it is very important to understand the difference between bevel and chamfer, so that we can choose the right machining method during the machining process. This article will tell you the definition, function and application of bevel and chamfer and whether the chamfer and bevel are worth considering in the design.

What is a Bevel?

A bevel is a bevel that connects two parallel surfaces of a part, any angle can be measured as a bevel and normally they are 45 degrees, and one of the main ways to process the bevel into an object is to use bevel tools.

What is a Chamfer?

Unlike a bevel, a chamfer is virtually always at a 45-degree angle. In order to prevent injuries during handling, chamfer can be used to eliminate the sharp edges from the part’s 90-degree angle. The resulting octagonal form is the outcome of the mathematics. Chamfers are made up of two parts: an outside chamfer (typically convex) and an inner chamfer (concave).

Bevel Vs Chamfer: Functions

- Bevels:Bevels are commonly used to soften the edges of different pieces of furniture, such as tables and mirrors, and to ensure that they do not cut people or provide a safety risk. The inclined surface can provide stability and wear resistance to the connected components, and this inclined edge is conducive to the assembly of the workpiece, while also improving the aesthetic and safety of the mechanical parts.

- Chamfers: There’s something visually appealing about chamfer. They also provide structural functions. Today, numerous sectors, from carpentry to product engineering and more, make use of the chamfered edge. These days, the chamfered edge is easily incorporated into a variety of materials, including stone, wood, plastic, and metal welding procedures. They are used to get rid of burrs for a more aesthetically pleasing appearance and to eliminate sharp edges for safety. Not to mention, in order to prevent cracks and lessen the possibility of deformation, bear steel must be chamfered during rough machining prior to heat treatment.

Bevel Vs Chamfer: Machining Method

- Bevels: Bevel machining usually uses bevel tools, here we introduce two bevel cutting tools. The first tool for beveling the plane is called plate beveling machine. The second tool for beveling the pipe is called pipe belveler, which removes the material from the edge of the pipe to create an angled beveling.

- Chamfers: The chamfer can usually be processed using a standard milling machine equipped with a chamfer end mill. In addition, chamfering on cylindrical billets can be produced by a rotary broaching process on a lathe.

Bevel Vs Chamfer: Shape

- Bevels: A bevel is the hypotenuse between two parallel planes, and it can be any Angle.

- Chamfers: The chamfer is usually cut at a 45 degree Angle. This slanted edge connects two adjacent surfaces of the workpiece.

How to Save Time and Cost When Chamfer and Bevel are Considered in Design

The processing of bevel and chamfer will generate additional costs and time, when part’s quantity is huge, production costs and time will increase significantly.

If the design does not require the function of chamfer and bevel, eliminating this design simplifies manufacturing, saving costs and production time. The role of the chamfer is to bring beauty to the part, remove burrs, and facilitate assembly. If these features are needed in the design, the manufacture of chamfer can be simplified by providing loose tolerances, or the chamfer feature can be removed in the CAD model and marked “remove all sharp edges” in the 2D drawing, which can save time and cost for manufacturing.