Turbine blades are widely used in the aerospace, automotive and power generation industries, and their manufacturing process is complex and sophisticated, requiring very advanced processing techniques and equipment to maintain quality and efficiency. The complex geometry and precision of the blades are key to being able to withstand extreme temperatures, pressures and speeds.

5-axis CNC machining plays an important role in the manufacture of turbomachinery components. Shanen offers precision 5-axis machining technology to ensure superior turbine blade quality. The minimum work range of 5-axis machine is 50*50*100mm, the maximum machine work range is up to 450*680*500mm, accuracy range 0.01mm-0.002mm. We will provide suitable equipment according to your needs for processing, to achieve reasonable cost control.

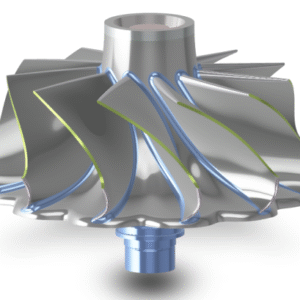

4 Methods for 5-axis machining of turbomachinery

Flank Milling:

Point Milling:

Integral Shroud Milling:

End Milling: