Sheet metal fabrication is a multifaceted manufacturing process involving transforming flat metal sheets into functional parts. It encompasses many procedures, and each modifies the metal for design requirements. With cutting, bending, punching, and welding methods, sheet metal fabrication converts metals into complex components. Its precision and adaptability characterize the process in industries requiring metal parts with exact specifications. From creating thin, foil-like elements to working with thicker plates, sheet metal fabrication utilizes a spectrum of metal gauges inversely proportional to their thickness. Thus, it handles different industrial applications.

Types of Sheet Metal Fabrication Techniques

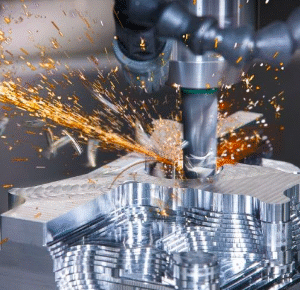

Cutting

In sheet metal fabrication, cutting is a subtractive process that shapes metal while removing parts of it. Techniques like laser, waterjet, and plasma cutting are employed. Laser cutting, for instance, uses a concentrated beam to slice through metal, ideal for thinner gauges. Meanwhile, waterjet cutting mixes water with an abrasive and cuts metals with low melting points without thermal distortion. Plasma cutting uses ionized gas that can penetrate thicker gauges quickly. However, it offers less precision than laser or waterjet methods. Remember that punching and blanking help create holes or shapes, which turn excess material into scrap or new workpieces.

Deformation

Deformation in sheet metal fabrication includes altering metal sheets without removing material. Bending refers to a principal deformation process, which employs tools like brakes to create V, U, and channel shapes in metal, with thinner gauges allowing easier manipulation. While utilizing hydraulic or mechanical presses, stamping shapes metal for tasks such as embossing or flanging without removing material. Another method is spinning, where metal is rotated on a lathe. It allows for the creation of symmetrical parts like cones and cylinders. Moreover, wheeling for compound curves and rolling for thickness alteration are less common but striking.

Assembly

In sheet metal fabrication, assembly combines cut and deformed pieces into a cohesive unit. It can be done through numerous methods, including using fasteners like bolts, screws, and rivets. Punching may be employed for appropriate holes for these fasteners. Further, welding is essential in assembling, melting, and fusing metal parts. It uses different welding techniques for different metals. The method solidifies the joint while guaranteeing an assimilated ultimate product.

Materials for Sheet Metal Fabrication

- Steel: Celebrated for its strength and stability, frequently utilized in heavy-duty functions.

- Stainless Steel: Delivers corrosion resistance for industrial and consumer products.

- Aluminum: Lightweight and corrosion-resistant in aerospace and transportation.

- Copper: Highly malleable and conductive for electrical and decorative elements.

- Brass: Resists corrosion and has acoustic properties for fittings and decorative items.

- Titanium: Recognized for its strength and lightweight properties in aerospace.

- Zinc: Regularly employed for coating other metals to shield against corrosion.

Design Considerations for Sheet Metal Fabrication

Material Selection

Material selection is key in sheet metal fabrication. It impacts the concluding product’s quality and suitability for its envisioned application. The choice of material, from aluminum and steel to exotic metals like titanium, swirls around strength requirements, weight considerations, environmental exposure, and electrical conductivity. For instance, stainless steel is chosen thanks to its corrosion resistance for medical or food-grade applications. Conversely, aluminum is preferred for its lightweight yet strong properties. It has become vital in the aerospace and automotive industries.

Geometric Accuracy

Realizing geometric accuracy is dominant in sheet metal fabrication so the parts fit in their intended assembly. It involves consideration of dimensions, tolerances, and the physical properties of the picked material. Factors like bend radii, angles, and the placement of holes and cutouts must be planned to support the functional requirements of the design. Note that inaccuracies in these elements can prompt assembly issues, structural weaknesses, and failure of the part to perform.

Applications of Sheet Metal Fabrication

- Automotive Industry:For components like panels, brackets, and chassis.

- Aerospace:In manufacturing aircraft frames, panels, and engine components.

- Construction:Employed in roofing, siding, and HVAC systems.

- Consumer Electronics:For enclosures and chassis in smartphones and computers.

- Medical Equipment:In producing surgical instruments and equipment housings.

- Robotics:For creating structural components and protective casings.

Benefits and Drawbacks of Sheet Metal Fabrication

Sheet metal fabrication offers benefits, notably that it can produce many parts. It allows for high-precision creation of custom, complex designs for industry needs. The process is also cost-effective for large-scale production. The main reason is that it produces the least waste and uses economical materials like steel and aluminum. Plus, sheet metal parts are recognized for their strength, durability, and capacity to tolerate punitive environments for industrial and consumer applications. The option for innumerable finishing techniques, including powder coating or anodizing, also augments the aesthetic and serviceable properties of the fabricated parts.

Still, there are drawbacks to sheet metal fabrication. The initial setup and tooling costs can be high for custom designs. It impacts the cost-efficiency of small-scale productions. The process’s flexibility is somewhat limited when dealing with highly complex shapes, and additional finishing processes may help accomplish the desired surface quality. But it adds to the production time and cost. Besides, the dependence on skilled labor for explicit fabrication techniques can influence the final product’s quality and uniformity. Despite these challenges, sheet metal fabrication remains a broadly used and irreplaceable manufacturing method across sectors.

Get in touch now for an estimate on your sheet metal fabrication requirements!