Screw threads are helical ridges that wrap around a cylindrical or conical surface to transfer rotational movement into linear force. They are key to mechanical engineering throughout sectors. For example, in CNC machining, the thread’s lead influences the mechanical advantage for precise control in lead screws. Even a single-threaded screw can attain axial movement with each turn.

In automotive and aerospace, many types of threads assemble jackscrews and valves with precise tolerances. Tapered threads like NPT offer leak-proof seals under high pressure in fluid dynamics. Parallel threads like BSPP keep consistent diameters for secure fittings. Knowing thread geometric parameters helps choose the proper thread type to satisfy engineering needs and reliability.

Main Types of Threads

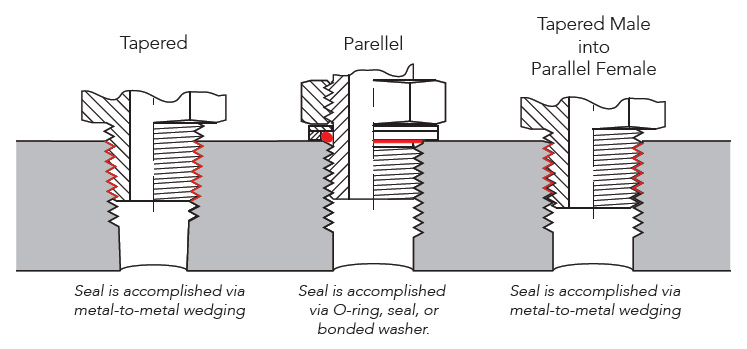

Parallel Threads

Parallel or straight threads have a uniform diameter across the threaded portion. It is important when a tight, continuous seal is not required from the threads alone, but an additional sealing O-ring or gasket is employed. BSPP, UN/UNF, and Metric Parallel threads are instances.

E.g., BSPP threads benefit hydraulic systems since their parallel profile lets a sealing washer to be located against the mating surface. With their 60-degree thread angle, UN/UNF threads balance strength and thread depth for precise aircraft fittings. In international engineering, metric parallel threads are desired owing to their compliance with standardized thread profiles and applications.

Tapered Threads

Tapered threads decrease in diameter for a tight seal when the male/female threads are connected. In high-pressure systems, the threads must seal without extra sealing components. That’s why the tapered characteristic is vital. Meanwhile, BSPT, NPT, and NPTF are some illustrations.

BSPT threads with a 55-degree thread angle and 1-in-16 taper are used for leak-proof metal-to-metal connections in gas and fluid transfer. In North American plumbing systems, NPT threads with a 60-degree angle and 1-in-16 taper help seal for water, steam, and oil. NPTF threads offer a dry seal while deforming slightly to fill gaps. They suit fuel lines to sidestep tragic leakage.

Detailed Types of Threads

- Right-Hand Threads: Right-hand threads tighten clockwise. It is usual for most applications. To avoid loosening, they fasten components using concurrent rotating forces.

- Left-Hand Threads: Left-hand threads tighten counterclockwise when rotational forces might otherwise loosen a right-hand thread. They are used in automotive components or gas supply valves. That’s where rotational direction could cause thread failure.

- “V” Shape Threads: “V” shape threads have a 60° angle and provide a grip with moderate manufacturing difficulty. They suit fasteners, nuts, and bolts. Additionally, lathes, taps, and dies help cut accurate threads for general-purpose fastening.

- Metric (International) Threads: Metric threads are marked by “M” and are standardized with a 60° thread angle. They are the go-to for international engineering projects. Used in automotive and aerospace, they offer a consistent thread profile to simplify manufacturing.

- British Standard Threads: British Standard Threads include BSW (Whitworth), BSF, BA, and BSP. For instance, BSW is used for heavy-duty fastenings and BSP for piping systems. They feature a 55° thread angle and are used in vibrations and dynamic loads.

- Seller Threads (American National Threads): The American Standards Institute defines Seller threads with a 60° angle and flat roots. They are utilized in North American industries (machinery and automotive) with crucial standardization.

- Square Threads:Among the types of threads, square threads have a flat, square cross-section for high efficiency in power transmission. Nevertheless, they are weaker than other types of threads, including “V” threads. Plus, they benefit screw jacks to decrease friction.

- Acme Threads: Acme threads have a 29° angle and are a modified square thread, stronger and easier to machine. They are used in lead screws, bench vices, and brass valves for load distribution and smooth operation. Their design lowers backlash in precision applications.

- Knuckle Threads: Knuckle threads are rounded for impact and dirt resistance. They are used in railway couplings or fire hose fittings for reliability and ease of assembly.

- Buttress Threads: Buttress threads feature a triangular profile with one side at a right angle to the axis to handle high axial loads in one direction. They suit heavy machinery and presses. That’s where the applied force must be concentrated in a single direction.

- Worm Threads: Worm threads are deep, helical threads with a 29° angle, like Acme threads. They are key to worm gears for smooth and precise motion transfer at a 90° angle. Their design delivers high torque transfer with negligible space requirements.

- Single and Multi-Threads: Single-thread screws have one continuous thread. Conversely, multi-thread screws have multiple threads running parallel. Multi-thread types of threads are used for rapid and precise movement in lead screws for CNC machines.

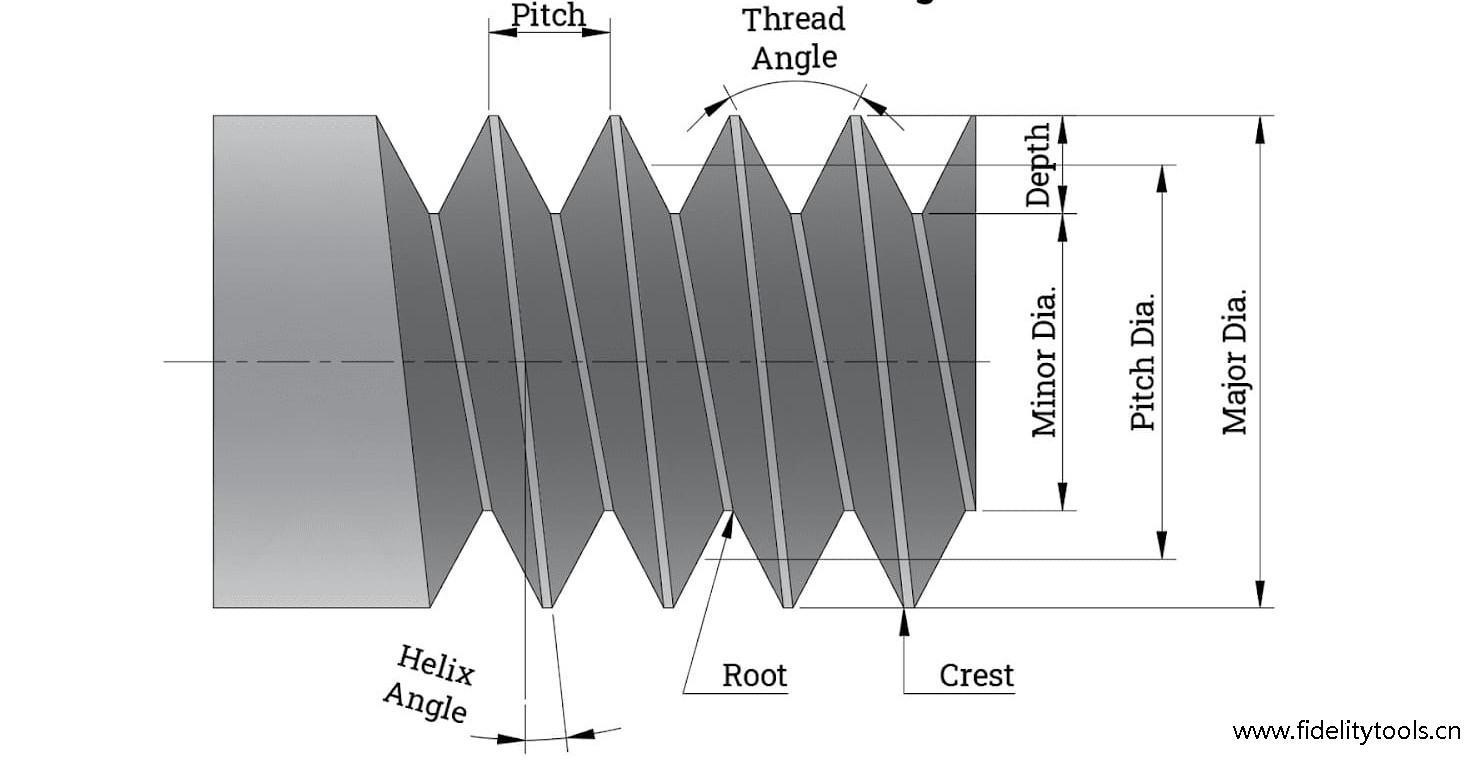

Geometric Parameters of Screw Threads

Major Diameter (Outer Diameter)

The major diameter is the thread’s largest diameter from crest to crest on a screw or from root to root in a nut. Accurate measurement encompasses calipers or a micrometer. It defines the nominal size of the thread and the fit and load capacity in numerous types of threads.

Minor Diameter (Inner Diameter)

The minor diameter is the smallest. It is found at the root of the threads on a screw or at the crest of a nut. It helps calculate the core strength of the thread under tensile stress. Measurement may require a floating carriage micrometer to assess latent weak points accurately.

Pitch Diameter (Effective Diameter)

The pitch diameter, or effective diameter, is the average diameter when the thread groove and ridge are equal. Fundamentally, it defines the thread’s fit and engagement characteristics. To calculate this, a thread micrometer balances the major and minor diameters.

Pitch

Points on neighboring threads are separated by pitch. Basically, it is measured parallel to the axis. Furthermore, it guarantees that the threads can engage without slipping or binding. Measurement might be accomplished using a pitch gauge in precision machining.

Lead

Lead alludes to the axial distance a screw thread advances in one complete turn. For single-threaded screws, it equals pitch. But, it multiplies with the number of thread starts in multi-threaded screws. Measuring lead is essential for precise linear movement in lead screws for CNC machines.

Thread Starts

Thread starts are the number of independent threads running along the screw. Remember, more thread starts increase the lead for faster axial movement with each turn. It is advantageous for precision applications that also necessitate rapid assembly or adjustment.

Helix Angle

The helix angle is the angle between the thread’s helix and a line perpendicular to the screw axis. It affects the screw’s efficiency in friction and load distribution. Note that a higher helix angle means lower friction, which is expedient in power transmission applications.

Thread Angle

The thread angle is between thread flanks. It impacts load distribution across the threads. A precise thread angle confirms that the load is uniformly distributed to disregard thread deformation under high stress to preserve the uprightness of different types of threads.

Tooth Angle

The tooth angle delineates the geometric shape of the thread profile. It can be triangular, trapezoidal, or square. Also, it determines the thread’s strength, wear resistance, and manufacturing complexity. Each form is chosen as per the load capacity and ease of fabrication of the application.

Do you need help in choosing the right types of threads for your project? Approach ShanenTech.