Customers from Singapore Yudo and Indonesia Yudo visited our mold production center on September 26, 2023.

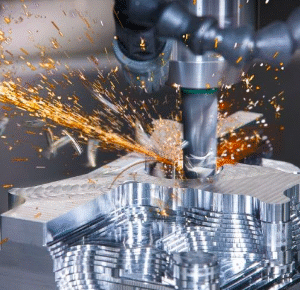

The purpose of Yudo customers’ visit is to understand our production capacity and equipment capabilities. We have CNC machining department, EDM department, grinder and milling machine center, assembly department, injection molding department, post-processing center and quality inspection department.

Now, join our customers as they explore our company’s rich history, advanced manufacturing processes and our employees’ passion for what they do.

Our customers first visited the EDM department, learned about the accuracy range of the machine, and asked employees about their understanding of the product. Our employees responded very cooperatively. As you can see, our machines are neatly arranged and the environment is clean and tidy.

Recently, we added two new Sodick EDMs, bringing the total to 8 EDMs. As the number of customers continues to increase, added machines are essential to ensure on-time delivery.

In the assembly department, Mr. Goh from Singapore Yudo gave us a brief introduction to Yudo’s hot runner. And our factory director explained our production conditions and capability range, a robotic arm is used to assist in the assembly of mold parts. All these effective information exchanges deepened our mutual understanding. Our factory director believes that the customer’s visit allowed us to understand our own shortcomings and advantages, and was inspired to manage production. We are unwaveringly committed to delivering molds with uncompromising quality that meet and exceed our customers’ expectations.

After visiting and understanding the QC department, grinding machine department and CNC machining department, we finally came to the injection molding department. During the busy period every year, the injection molding department will have two shifts.

When it comes to the environmental impact of plastic manufacturing, we are committed to proactively reducing our impact on the environment and have implemented a range of initiatives throughout our operations to reduce waste, conserve energy and promote environmentally friendly practices.

We are very grateful to our Yudo customers in Singapore and Indonesia for visiting us. During the communication, we gained an in-depth understanding of Shanen’s strengths and weaknesses, which will be of great help to our company’s future planning.

We welcome you to visit and learn about our 13-year transformation journey from workshop to factory, learn about the innovation in our factory, and work together with our passionate team. If you have any project that needs our support, please do not hesitate to contact us!