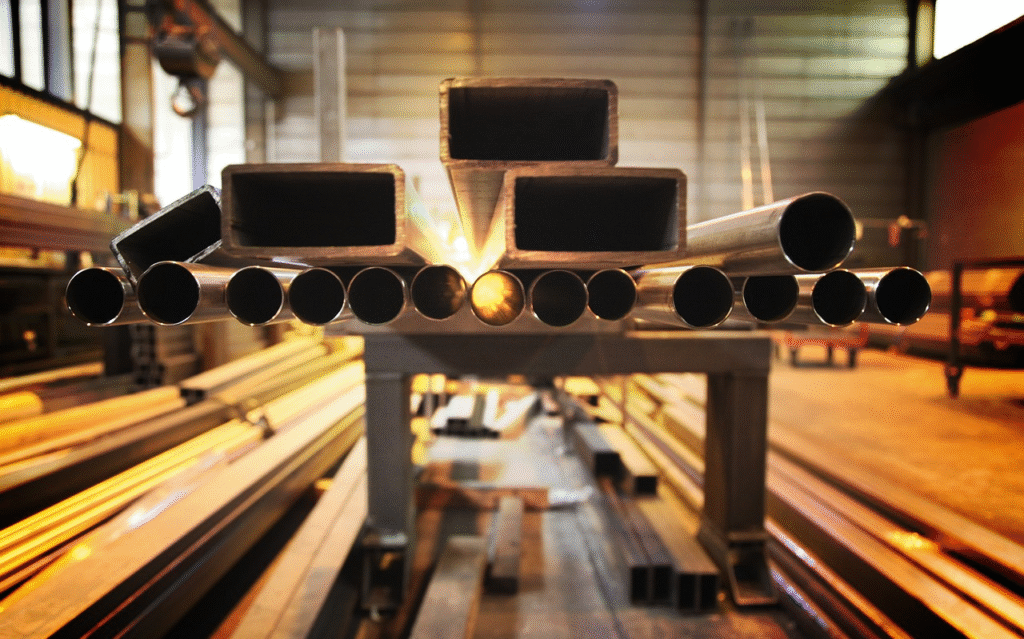

Traversing the world of metallic components can be a complex endeavor, mainly when choosing between galvanized steel vs. stainless steel. Both materials offer unique advantages and attributes for numerous applications, which renders the decision anything but straightforward. In this article, we investigate into both materials’ technical aspects, characteristics, and applications. It helps ensure you have a thorough understanding to make a choice bespoke to your needs.

Composition and Alloying Elements

Galvanized Steel:

When you choose galvanized steel, you select a material protected by a strong zinc coating. The material is a product of a process where steel is submerged in molten zinc. It results in a protective layer that fiercely guards against rust and corrosion. Over time, this exterior might witness wear and tear. Still, its primary function of protecting the core steel structure remains steadfast.

Stainless Steel:

Opting for stainless steel means investing in an alloy, which is predominantly of iron but improved with a minimum of 10% chromium. However, this combination may also include elements like nickel and molybdenum and hence culminates in a highly resistant material. Chromium plays a fundamental role in encouraging the formation of a protective layer that guards the material against various forms of corrosion. As a result, this guarantees its endurance and sustained performance.

Strength and Durability

Galvanized Steel:

Galvanized steel expresses its strength through a formidable zinc layer, which heightens its durability. Notably, hot-dipped galvanized screws offer tensile strength upward of 62,000 PSI. But again, keep in mind that the protective zinc layer is susceptible to degradation over time. It may compromise the core steel’s integrity while affecting its prolonged existence.

Stainless Steel:

In contrast, stainless steel claims intrinsic durability throughout its composition, not just on the surface, thanks to its alloying elements. It shows superior integral robustness with a tensile strength ranging between 100,000 to 150,000 PSI. Undoubtedly, this inherent characteristic confirms that the material preserves its integrity over protracted periods, even in challenging conditions.

Rust and Corrosion Resistance

Galvanized Steel:

The zinc coating is the guardian of galvanized steel and provides a vigorous defense against rust. Nevertheless, in instances where the coating wears off due to consistent wear and tear and other factors like the change in thickness of the coating and the environment in which the steel is placed, the underlying steel becomes defenseless. Such exposure allows moisture and other corrosive agents to compromise the steel. Subsequently, this diminishes its features and effectiveness.

Stainless Steel:

Stainless steel presents a formidable defense against corrosion. It contains chromium, which reacts with oxygen to form a thin and shielding layer of chromium oxide on the steel’s surface. Consequently, chromium adopts a passive film and safeguards the material against various corrosion forms. However, you should consider environmental variables like exposure to saline or low-oxygen environments. They can challenge stainless steel’s resilience.

Thermal Resistance

Galvanized Steel

Galvanized steel possesses moderate thermal resistance. It can tolerate temperatures up to 392°F (200°C), beyond which the zinc layer deteriorates and the steel oxidizes. It renders galvanized steel appropriate for applications that do not involve extreme or fluctuating temperatures.

Stainless Steel

Stainless steel, however, exhibits superior thermal resistance. It upholds its structural integrity and resistance properties even at elevated temperatures. For example, austenitic stainless steels with at least 18% chromium can commendably operate at temperatures exceeding 1500°F (816°C). It is ideal for high-temperature applications like furnace components and heat exchangers.

Cost-Effectiveness and Value

Galvanized Steel:

Galvanized steel is a cost-efficient option in projects with predominant budget constraints. While it offers essential protective features and reasonable durability, it requires consideration of the long-term implications of potential wear and replacement costs. In cases where the coating is damaged, re-galvanization may be necessary to restore its protective properties.

Stainless Steel:

While stainless steel has a higher upfront cost, it epitomizes long-term investment and offsets initial expenses with durability and less upkeep needs. Its enduring nature and resilience against corrosion position it as a material that offers substantive value over time. Essentially, it remains unaffected by environmental factors for reduced maintenance checks or reparative actions.

Applications

Galvanized Steel:

- Suitable for outdoor constructions and ductwork, where strength and durability are key.

- Utilized in car bodies and parts for its rust and corrosion resistance.

- Ideal for use in environments that are not excessively corrosive.

- Used in roofing owing to its durability and the protective attributes of its zinc coating.

- Common in utility hardware, including poles and cables.

Stainless Steel:

- Its non-reactive nature renders it fit for applications that demand high levels of hygiene. These include kitchen utensils and food processing equipment.

- Also prevails in sanitary applications such as plumbing.

- Utilized in medical instruments and equipment, thanks to its ease of sterilization.

- Exhibits excellence in architectural and decorative applications due to its aesthetic appeal.

- Preferred in machinery and tools because of its strength and corrosion resistance.

Which Material is Better?

In the confrontation of galvanized steel vs. stainless steel, determining a clear victor is contingent upon your needs and application requirements. Galvanized steel offers a rugged, cost-efficient option for several external applications. However, with its intrinsic corrosion resistance and greater durability, stainless steel presents a choice for long-term applications despite its higher initial cost. The decision lies in aligning material attributes with your project’s nuances and expectations. Thus, it certifies that the chosen material delivers performance, durability, and value.