Order quantity from 1 to 10000 pieces

One-to-one support service response within 8 hours

Tightest tolerance ±0.002mm

Best surface roughness Ra 0.2μm

ISO 9001:2015 certified

Why Choose Us for CNC Machining

Decades of Expertise and Modernization

ShanenTech blends history and ingenuity in CNC machining with over a decade of involvement. Our 35+ skillful engineers have accomplished over 3,000 projects with made-to-order solutions for numerous materials and difficulties. Our knowledge permits us to comprehend CNC machining and anticipate and disentangle each project’s concerns. Our relentless learning and responsiveness put us at the top of our game, ready to realize your demands with experience.

Cutting-edge Technology and Precision Machinery

ShanenTech has trailblazing CNC milling, turning, and 5-axis machinery. Our arsenal allows us to accurately and expeditiously handle projects of any scale. We use the up-to-date technologies to guarantee your items fit defined requirements from prototype to production, not simply for innovation. This ISO 9001:2015 accreditation displays our obedience to workmanship and exactness in every component we make.

Stanch Precision and Reliability

Precision is our undertaking, with the tightest tolerances up to ±0.002mm and the best surface roughness up to Ra 0.2μm. Our CNC machining manufactures components that conform to your requests. Each item is 100% inspected for tolerances and immaculate finishes. Our one-to-one support service promises a 12-hour response. ShanenTech delivers precision-engineered components and unswerving help from start to finish.

Industries Served

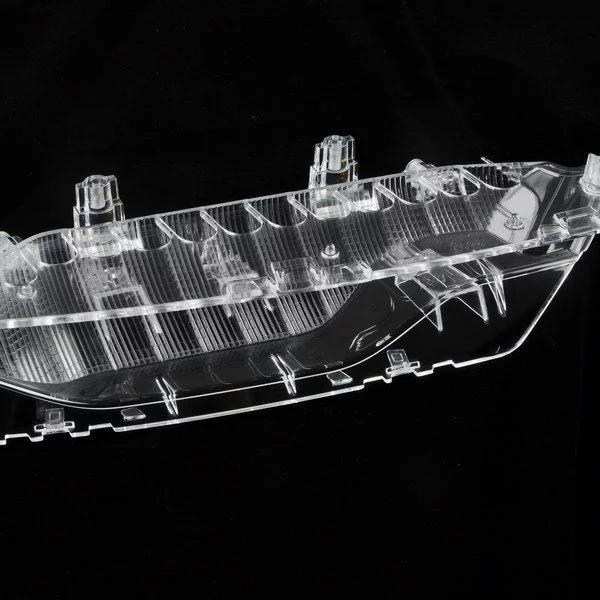

ShanenTech’s experience in aerospace, automotive and medical illustrates our capacity to crack each sector’s problems. Our aerospace customers trust us to manufacture multifaceted, high-precision parts. The automobile sector benefits from our solid and reliable parts. Further, our medical items fulfill tight governing criteria.

What We Good At CNC Machining Processes

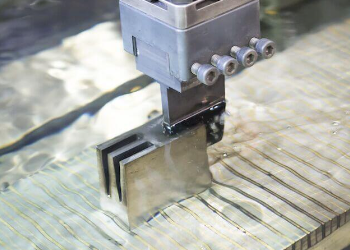

CNC Milling

CNC milling is a precision subtractive manufacturing method that processes materials such as metals and plastics into geometric shapes that designers want to meet industrial needs. It is suitable for machining precision parts in industries.

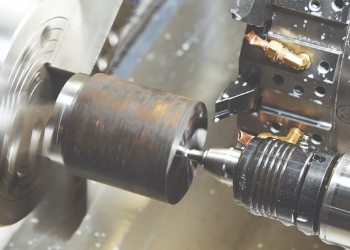

CNC Turning

CNC turning is a subtractive machining method that can manufacture geometric shapes, internal holes and various threads. This method removes excess material by using a tool to rotate at high speed over the material to get the final design result, which is usually a round or tubular part.

Lathe Machining

CNC lathe machining is the ideal choice for the production of round parts. Our CNC lathe machining capabilities range from very small to very large capabilities, and it can correctly produce complex parts with high precision.

EDM

Electric discharge machining uses electrical discharge for precision machining, especially in precision designs.

ShanenTech Provides Custom Designed and Verified Prototype Machining for Industries

Prototyping is the process of manufacturing metal and plastic parts using CNC machining, and repeatedly verifying that the parts designed by the design team are suitable for industrial needs. In addition, it is a economical method to help verify and improve the design.

Our prototyping services include design assistance, which allows you to know the state of the process through timely feedback on the results at each stage of the production process, making it easier to know if the design needs further improvement.

Custom Machining for Low-Volume Production

CNC machining has the characteristics of low error rate, high production efficiency and high automation accuracy, which is especially suitable for the production of small batch customized parts in many industries.

Our CNC machining shop can provide the fastest production cycle for the customized product or part, and provide a comprehensive service solution, including heat treatment surface treatment.

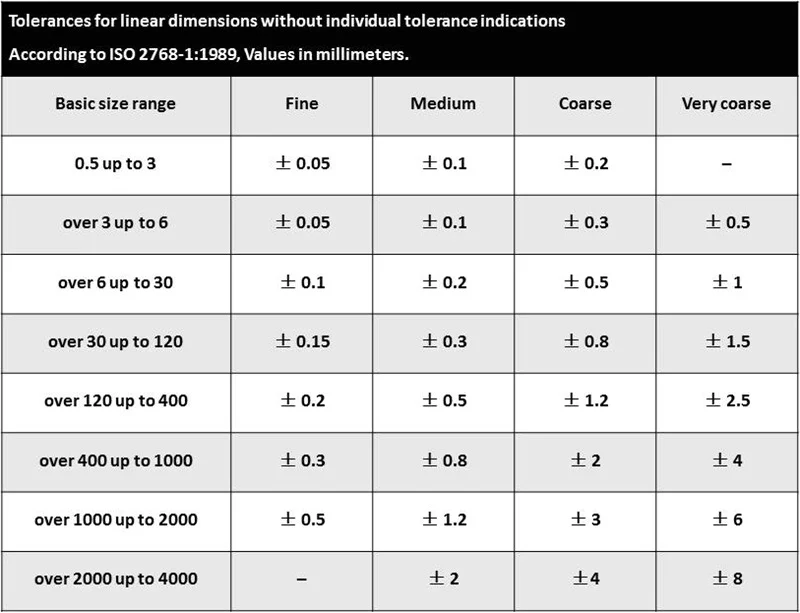

CNC Machining Tolerance

Shanen’s standard tolerance is applied to ISO 2768 (medium) for machined plastic and ISO 2768 (fine) for machined metals. We provide custom-made machining services for several design and engineering wants. Our tolerances range from ±0.125mm to ±0.002mm while beating the highest accuracy requirements. From as-machined to the up-to-the-minute surface treatments, we can customize the product to your needs. Our team cooperates with you to set and realize your project’s dimensional tolerances.

How to Get Started with Your CNC Machining Project

Initiating Your Project

It's cool to start a CNC machining project with us. Contact us by phone or email to discuss your project. Please send us your concept or CAD file so that our engineers can evaluate it. This first conversation helps to understand your request and ensure the implementation of the project.

Learning the Quote Process

After analyzing your drawings and specs, we give a wide-ranging quotation with the project scope, lead-time, and prices. We will provide cheap prices without losing quality to meet your financial plan and project intentions.

Dedicated Customer Service Support

Our customer support staff provides enduring communication and updates throughout the process. We promise one-on-one help within 8 hours.

Contact Us to Start Your CNC Machining Project

Our CNC machining services from prototype to production ensure high quality, fast delivery and competitive prices.