Wire Electrical Discharge Machining, or wire EDM cutting, refers to a precision machining technology that removes material utilizing electrical discharges between a thin wire electrode and a conductive workpiece. Wire EDM cutting employs heat energy to evaporate material for precise, convoluted patterns. On the other hand, CNC machining uses physical cutting tools. Remember that spark erosion, wire erosion, wire burning, and spark machining are synonyms.

Early wire EDM expansion started in the Soviet Union. Joseph Priestley revealed electrical discharge effects in 1770. The Lazarenkos improved the idea in the 1940s. Soviet researchers created the first wire EDM machines in the 1960s. 20th-century led to present high-precision uses.

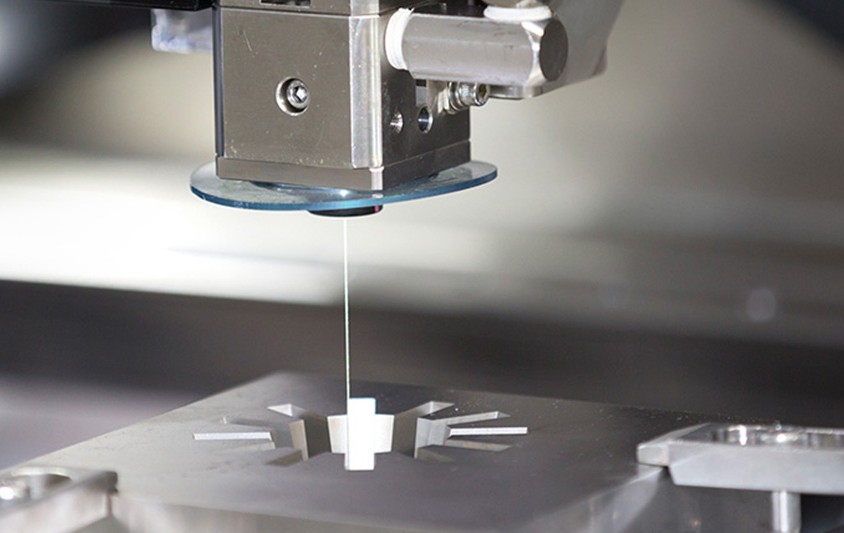

How Wire EDM Works

Operational Principles

Wire EDM cutting removes material from conductive workpieces using controlled electrical discharges. A thin brass or multilayer copper wire electrode is immersed in deionized water as the dielectric fluid. When high voltage is applied, the space between the wire and the workpiece generates sparks. These sparks heat and evaporate small amounts of material to cut without touch. The technique is precise enough for complicated geometries and tight tolerances.

Components of a Wire EDM Machine

- CNC Control: High-precision stepper motors and programming.

- Dielectric Fluid: Commonly deionized water.

- Electrodes: Cathode (wire) and anode (workpiece).

- Wire System: Tension and speed control.

- Working Table: Support and movement mechanisms.

- Power Supply: Voltage and pulse control.

- Recycling System: Debris removal and fluid filtration.

Key Considerations in Wire EDM

Types and Dimensions of EDM Wire

Brass, copper, tungsten, molybdenum, zinc-coated, and diffusion-annealed wires are utilized in wire EDM cutting. Thanks to its conductivity and affordability, over 80% of EDM applications employ brass with a diameter of 0.010 inches. For tougher materials, tungsten and molybdenum have stronger tensile and wear resistance. Tensile strength, electrical conductivity, and fracture resistance should be considered when selecting a wire. Thick wires cut quicker but less precisely. Conversely, fine wires with diameters as small as 0.0008 inches are precise for detailed drawings.

Part Geometry and Design

Wire EDM cutting is influenced by part geometry. Multifaceted shapes and sharp interior corners might make wire handling difficult and breakable. Consequently, for smooth cuts, create corners wider than double the wire diameter. Furthermore, draft angles and relief holes enable wire access and circumvent erosion. Deep slots need room for wire movement and flushing. Flat pieces may be stacked for unattended batch processing to conserve time and material.

Surface Finish and Tolerances

Wire EDM cutting produces precise surface finishes and tolerances, which may reach ±0.0001 inches. Surface finish quality can be as fine as 3 microinches for aerospace and medical components. Wire tension, dielectric fluid quality, and machine stability affect accuracy. Particle flushing and spark erosion are necessary for high-quality surface finishes, so steady dielectric fluid flow is key. After roughing, fine cuts improve surface polish and satisfy tolerances.

Material Thickness and Conductivity

Wire EDM cuts thin to medium-thick materials well. The hardness and conductivity of pre-hardened die steels, titanium, and austenitic stainless steels make them ideal. Titanium’s high conductivity lowers heat to retain dimension accuracy. Although machinable, copper and brass have lower melting temperatures and quicker wire wear. It renders them less cost-effective. Wire EDM’s slower cutting speeds may make conventional machining more efficient for thick materials.

Programming and Control

Boosting wire EDM cutting demands CNC programming efficiency. Use CAM software for accurate toolpaths and travel time-saving. Corner rounding and spark gap control handle tight curves and thin features. Use virtual wire pathways to see problems early and prevent expensive blunders. Automatic wire threading systems eradicate delays between cuts for productivity. So, the precision and quality of the machined item depend on CNC control and program verification.

Applications of Wire EDM

- Automotive: Wire EDM cutting helps manufacture cylinder heads, valves, and fuel injectors. It can realize tolerances of up to ±0.0005″ for precise fits in engine components.

- Aerospace: In aerospace, wire EDM cutting creates tricky shapes in landing gear and engine parts. It keeps tolerances as tight as ±0.001 mm for high-stress/temperature settings.

- Medical Device: Wire EDM produces surgical instruments, orthopedic implants, and dental tools. It provides precision down to ±0.0001″ for conformity to medical standards.

- Electronics: For microelectrodes, connector pins, and lead frames, wire EDM cutting offers micron-level precision. It preserves the reliability of electronic components.

- Die Tooling: Wire EDM creates injection molds and stamping/extrusion dies. It allows for complex 2D/3D shapes with tolerances as fine as ±0.0002″ for better die tooling quality.

Choosing the Right Wire EDM Service Provider

Consider multiple variables while selecting a wire EDM service provider. Check results for uniformity and quality first. Suppliers must offer precise components with micro-finishes. Assess their technologies and skills. CNC control systems, AWT, and adaptive machining handle complex contours and save interruption. Prioritize field experience and knowledge. Providers with aerospace and medical device manufacturing experience may satisfy rigid criteria. Finally, ensure precision and attention to detail. The supplier should use high-precision stepper motors, wire tension control, and dielectric fluid management for machining accuracy and surface authenticity.

Shanentech shines in wire EDM. Their technology and skills assure precise parts for key uses.