Why Choose Us for Acrylic Fabrication

Choosing ShanenTech means working with an acrylic fabrication leader who always delivers perfection. Our knowledge and technical infrastructure enable us to manage projects of any size and complexity. Quick turnaround: sample lead times are 5 days, and production cycles are 10 to 18 days for quantities up to 10,000 pieces. We provide customers with a full-service solution that is adjusted to their requirements and supported by tech experience and quality.

Our Fabrication Process

Cutting and Machining

Shanentech uses project-specific precision cutting methods. High-performance applications need complex designs and tight tolerances, which we deliver using laser cutting and CNC machining. We strengthen our cutting operations to lessen material waste and boost production efficiency.

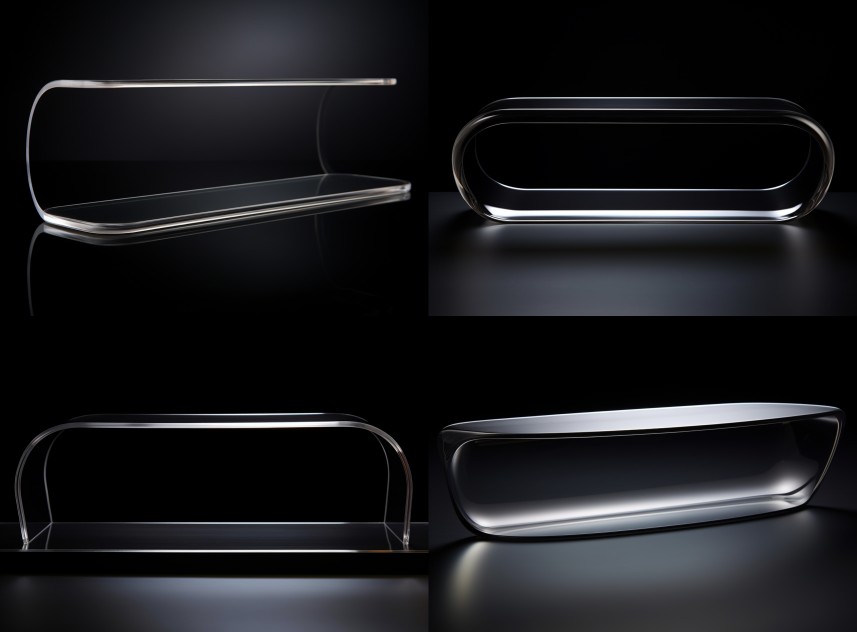

Bending and Molding

Our heat and solvent bending methods enable us to produce convoluted shapes and curves without impairing the material. At the same time, contemporary injection molding and thermoforming empower us to create huge numbers of components with unaltered quality and correctness. These approaches allow us to address a range of consumer requests across industries.

Custom Solutions and Applications

We excel in bespoke acrylic fabrication for clients. Whether creating custom components for retail displays or engineering specialized parts for automotive systems, our process starts with a detailed consultation to realize the project requirements. Our engineers and designers collaborate with customers to create rapid prototypes so the final product fits their needs.

Industry We Served

We use the material’s properties to create quality solutions for many sectors. After seeing acrylic’s promise early on, we’ve honed our ability to manipulate this polymer to meet client demands. Our acrylic solutions are creative and precise, from complex architectural to sensitive electrical components. We prioritize sustainability and efficiency so every project fulfills or surpasses its practical and aesthetic requirements.

- Advertising

- Engineering

- Furniture

- Electronics

- Automobile

Benefits of Acrylic Products

Optical Clarity and Transparency

Acrylic’s optical clarity renders it impeccable for applications that need transparency and a glass-like appearance without weight or fragility. Using particular approaches to increase this quality, we create items, including protective barriers and lighted signs, which maintain clarity under different lighting circumstances and are both practical and attractive.

Lightweight and Impact Resistance

Our acrylic products are lightweight and simple to handle, install, and transport, which are considerable benefits. Meanwhile, acrylic is useful in aircraft and automobiles, where weight reduction is indispensable for performance and fuel economy. Its impact resistance renders it durable while limiting replacements and outlasting many other materials.

Chemical and Climate Resistance

We treat acrylic items to make them chemical- and weather-resistant. It makes them appropriate for tough external applications, including architectural outside panels and engineering protective coverings. Our treatment procedures keep the material looking good and performing efficiently even when bombarded by contaminants, dampness, and UV radiation.